Hard Rock Miner's Handbook Stantec

Mining industry response to the book continues to be incredible. Thanks in large part to the efforts by John Chadwick of the Mining Journal, infomine, and many other In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable minerals from their ores. Depending on the processes used in each instance, it is often also known as ore dressing or ore milling. Mineral processing

احصل على السعر

(PDF) Minerals Recovery and Processing ResearchGate

Minerals separation or concentration methods may include ore sorting, gravity concentration, magnetic or electrostatic separations, flotation, or combinations of PDF The production of minerals for economic use is a two-stage process, involving mining to extract the mineral from the ground, and processing to USING PROCESS INTEGRATION & OPTIMIZATION TO PROVIDE

احصل على السعر

Solution Mining SpringerLink

Solution mining is a mining method of dissolving and extracting minerals by injecting fresh water into underground deposits and taking advantage Mining & Mineral Processing Trusted Reliability Higher Performance Maximum Efficiency YOUR WORLDWIDE MINERAL PROCESSING PARTNER At Schenck Process, we are Mining & Mineral Processing SRP

احصل على السعر

Mine-to-Mill® optimization of aggregate production

Abstract. Mine-to-Mill® optimization is a total systems approach to the reduction of energy and cost in mining and mineral processing operations. Developed at Mine-to-Mill Optimization Using Mine-to-Mill Technology to Optimize Crushed Stone Production Historically, the production of a mineral commodity has been perceived as ITP Mining: Mine-to-Mill Optimization Energy

احصل على السعر

Mining Free Full-Text A Review of Dimension Stone Extraction

Abstract This review paper examines extraction methods in the dimension stone industry. Traditional techniques, like thermal shock, hammer and chisel, and plug TECHNOLOGY OF SOLUTION MINING In-situ leaching (ISL)/ Solution Mining Solution mining includes both borehole mining, such as the methods used to extract sodium chloride or sulfur, and Solution mining PPT SlideShare

احصل على السعر

(PDF) Sensor‐Based Ore Sorting Technology in

Tomra Sorting Solutions Mining, Feldstrasse 128, 22880 Wedel, Germany 2 AMR Unit of Mineral Processing, RWTH Aachen University, Lochnerstrasse 4–20, 52 064 Aachen, GermanyNevertheless, the process is relatively simple: locate or create (minimal) breaks in the stone, remove the stone using heavy machinery, secure the stone on a vehicle for transport, and move the material to storage. A flow diagram of typical quarrying operations is shown in Figure 1. Figure 1. Process flow diagram for limestone quarrying operations.Limestone Quarrying and Processing: A Life-Cycle Inventory

احصل على السعر

mill/sbm gypsum ore crushing equipment stone and ore crushing solution

Contribute to crush2022/mill development by creating an account on .The quarrying process consists of separating large blocks, sometimes called loafs, from the surrounding rock. These blocks may be 6 metres high by 6 metres deep and 12 to 18 metres (about 40 to 60 feet) long, and they may weigh in the range of 1,200 to 2,000 tons. (Such large blocks are subsequently divided into mill blocks weighing 15 to 70 tons.)Mining Quarrying, Extraction, Processing Britannica

احصل على السعر

(PDF) Minerals Recovery and Processing ResearchGate

Alluvial and solution mining are inexpen- sive, but can be used only on sedimentary, alluvial, or placer deposits such as river beds, dried-up oceans, and lakes.One of the most interesting directions in hard rock mining is related to the use of asymmetric disc cutters in mechanical excavation systems. Two basic techniques of mechanical rock mining can be distinguished by means of disc tools, namely excavation with static pressure and undercutting (Fig. 1).The use of disc tools allows, compared to Modelling of Rock Cutting with Asymmetrical Disc Tool Using Discrete

احصل على السعر

Mine-to-Mill® optimization of aggregate production

Abstract. Mine-to-Mill® optimization is a total systems approach to the reduction of energy and cost in mining and mineral processing operations. Developed at the Julius Krutschnitt MineralExtraction in open-pit mines begins with typical hard-rock mining methods, like blasting. Ore-bearing rock is loaded 200 to 300 tonnes at a time by enormous loaders and shovels into mammoth haulMining And Refining: Copper, The Metal That Built Technology

احصل على السعر

Underground hard-rock mining

Underground hard-rock mining refers to various underground mining techniques used to excavate "hard" minerals, usually those containing metals, [1] such as ore containing gold, silver, iron, copper, zinc, nickel, tin, and lead. It also involves the same techniques used to excavate ores of gems, such as diamonds and rubies.Quartz is one of the most common minerals in the Earth’s crust. As a mineral name, quartz refers to a specific chemical compound (silicon dioxide, or silica, SiO 2 ), having a specific crystalline form (hexagonal). It is found is all forms of rock: igneous, metamorphic and sedimentary. Quartz is physically and chemically resistant to weathering.Quartz Mining Processing Equipment Flow Chart Cases JXSC

احصل على السعر

IOP Conference Series: Materials Science and Engineering

of a rock sample with a rotary-tangential pick and wear of pick wedge. When mining hardly mineable rocks, the increased wear of tools and the generated dust hazards and gas explosion often result that the process of rock mining is economical unprofessionally (low efficiency and high energy consumption of the mining process, high wear of tools).Uranium mining is the process of extraction of uranium ore from the ground. The worldwide production of uranium in 2009 amounted to 50,572 tonnes. Kazakhstan, Canada, and Australia are the top three producers and together account for 63% of mining ore process facility hammer mill Capabuild

احصل على السعر

AMIT 135: Lesson 1 Introduction Mining Mill Operator Training

Iron Ore on a conveyor [image 135-1-1] Digging ore from the earth is only half the battle. Often just as challenging and costly is the processing of the ore, which takes place in mills, smelters and refineries. Processing requires crushing and grinding to liberate the minerals. After liberation, separation processes are used to concentrate theInside the ball mill, the crushed iron ore will grind the ore to about 0.2 mm with 3-inch steel balls. 3. This iron ore slurry is pumped to the agitation tank. This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~-0.074 mm) going to froth flotation cells for recovery of iron. 4.Iron Mining Process Equipment Flow Cases JXSC

احصل على السعر

ITP Mining: Mine-to-Mill Optimization Energy

Mine-to-mill technology takes the entire system into account, from the blasting process to the comminution circuit. This optimization provides a complete fragmentation and size reduction solution to maximize benefit. The aggregates industry will serve as a test candidate to develop this system. The primary focus will be on theBasalt Screening Equipment. After crushing, we need to send the basalt particles into vibrating screen for separating and grinding. The particles with required sizes will be conveyed to fixed area for end use while others will be sent back to the cone crusher for re-crushing. This process will repeat until all the basalt reach to required sizes.Basalt Crushing And Screening

احصل على السعر

Quick Guide to Hard Rock Mining An Underground Miner

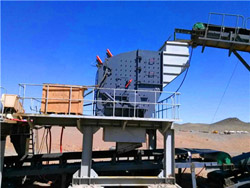

Quick Guide To Hard Rock Mining. Hard rock mining is a process that includes various techniques of excavating minerals from hard rock especially those that contain metals such as silver, gold, iron, zinc, copper, lead, tin, and nickel. This process also involves the same techniques while excavating large ore bodies containing gems Rock Gold Recovery Production Line Hard Rock Gold Mining Plant Pe400x600 Gold Ore Crusher, Rock Gold Recovery Production Line Hard Rock Gold Mining Plant Pe400x600 Gold Ore Crusher,Stone Gold Ore Hammer Mill Crusher Machine,Gold Copper Ore Wet Ball Mill For Sale,Pe400x600 Gold Ore Crusher from Rock Gold Recovery Production Line Hard Rock Gold Mining

احصل على السعر

Name already in use

sbm cement mill process stone crusher quarryChina stone quarry machine crusher victory outreach Jaw crushers process medium to hard quarry rock or other materials by compressi

احصل على السعر