Concrete aggregates properties crushed by jaw and

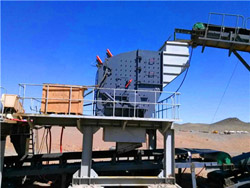

open access Abstract This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, In this study, two different crushing sequences are considered to evaluate the effect of the production process on the shape properties of aggregates viz., jaw-cone Effect of crushing mechanism on the shape properties of coarse

احصل على السعر

(PDF) Influence of Natural Aggregate Crushing Process on

The aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type. Aggregate crushing was carried out in a Los Angeles drum, in...Resistance to grinding is related to the strength of the products made from aggregates subjected to grinding, which affects the overall quality of these products. Influence of Natural Aggregate Crushing Process on Crushing

احصل على السعر

Numerical simulation of influence of coarse aggregate crushing on

The uniaxial compression test of concrete is simulated with coarse aggregate crushing, and the changes in stress–strain curve and compressive strength Considering that the optimal crushing sequence only consists of gradually increasing system strokes if the first two compressions are disregarded, new Implementation of optimized compressive crushing in full scale

احصل على السعر

Understanding Effects of Crushing Mechanism on Aggregate

The study uses basaltic aggregate produced from two different crushing mechanisms (i) jaw, cone and VSI (vertical shaft impactor) as primary, secondary and The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing Evaluation of size reduction process for rock aggregates

احصل على السعر

Comparison of Shape Parameters and Laboratory Performance of

The coarse aggregates from two type of crushing operations, (1) a series of jaw (J)-cone (C)-vertical shaft impactors (V), called JCV, and (2) a series of jaw (J) Most aggregate producers are well acquainted with the selection of crushing equipment and know it is possible to select a piece of equipment based solely on spec sheets and gradation calculations. Still, Selecting the right crusher Pit & Quarry

احصل على السعر

Preferential sequence crushing of copper ore based upon high

Preferential sequence crushing of copper ore based upon high-voltage pulse technology. Author links open overlay panel Guanghui Yan a, Zhenxing Zhang a, (The selected sample is not the quartz aggregate, after electrical crushing, due to the selective breakage of high voltage pulse, the quartz aggregate is hard to breakage,Abstract. Present paper showcase the optimization of crushing parameters through Taguchi methods to improve the production yield of the aggregate produced. The main objective is to investigate the impact of various crushing parameters like feed rate to jaw crusher and eccentric speed of Jaw crusher, closed side setting and throw in cone Optimizing processing parameters of stone crushers through

احصل على السعر

OPTIMIZATION OF COMPRESSIVE CRUSHING Chalmers

optimize the compressive crushing of these rock materials and ores. The obtained results indicated that optimal compressive crushing differs depending on the application and optimization objective. Different types of crushing applications, such aggregate and mining, should therefore not be operated in the same way.The ceramic waste crushed tiles were partially replaced in place of coarse aggregates by 10%, 20%, 30%, 40% and 50%. Rebutted tyre waste and ceramic tile powder were replaced in place of fine aggregate by 10% along with the ceramic coarse tile. M25 grade of concrete was designed and tested.(PDF) AGGREGATE CRUSHING PLANT Birhanu Shiferaw

احصل على السعر

(PDF) RELATIONSHIP BETWEEN AGGREGATE CRUSHING VALUE

The crushing value of aggregate could not surpass 45% for aggregate utilized for concrete other than for surfaces wearing, and 30 percent for the body of concrete used for surfaces wearing i.eThe aggregate shape properties produced from the different crushing techniques influence the performance properties of the asphalt mixtures. The objective of this study was to classify theComparison of Shape Parameters and Laboratory Performance

احصل على السعر

10.1016/j.minpro.2006.08.004 DeepDyve

Comminution in typical hard rock quarries is sketched in Fig. 1 . ASTM particle size distributions of select aggregate products are also shown in Fig. 1 ( ASTM, 2000 ). Crushing operations can accommodate some adjustment to match the demand for each gradation. Crushers used for hard rock are sketched in Table 1 .In order to analyze the impact of different crushing processes on the size of coarse aggregates, the aggregate conditions processed by Furong Quarry in Guangdong Heyuan were investigated, and the aggregates of 10~15 mm specifications of three processing processes were collected, respectively: ① Process 1: counterattack Buildings Free Full-Text Research on Three-Dimensional

احصل على السعر

comparative Life Cycle Assessment between recycled aggregate

and crushing is undertaken by crushers until a size of between 4 mm and 32 mm is obtained (Suárez, 2017). In the process of obtaining recycled aggregate from concrete, we considered internal transport in the aggregate production mine. External transport was not in-cluded, since extraction mines are usually located very close to the The aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type. Aggregate crushing was carried out in a Los Angeles drum, in accordance with the A comparative study between cone crushers and theoretically optimal crushing sequences. Miner. Eng. 2011, 24, 188Influence of Natural Aggregate Crushing Process on Crushing

احصل على السعر

Optimizing processing parameters of stone crushers through

Abstract. Present paper showcase the optimization of crushing parameters through Taguchi methods to improve the production yield of the aggregate produced. The main objective is to investigate the impact of various crushing parameters like feed rate to jaw crusher and eccentric speed of Jaw crusher, closed side setting and throw in cone The principal aggregate tests of rocks in the laboratory include aggregate crushing, aggregate impact, aggregate indicate that they were derived from a shale-greywacke sequence of(PDF) The Suitability of Some Selected Granite

احصل على السعر

(PDF) Influence of Natural Aggregate Crushing Process on Crushing

The aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type. Aggregate crushing was carried out in a Los Angeles drum, in accordanceThe aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type. Aggregate crushing was carried out in a Los Angeles drum, in accordance with the A comparative study between cone crushers and theoretically optimal crushing sequences. Miner. Eng. 2011, 24, 188Influence of Natural Aggregate Crushing Process on Crushing

احصل على السعر

DISCRETE ELEMENT MODELING OF INFLUENCES OF AGGREGATE

5.9 An Example of a Single Aggregate Crushing Load-Displacement Curve. 109 5.10 A Photo of a Crushed Aggregate Particle .. 109 5.11 Single Aggregate Crushing Average Results .. 112 5.12 Single Aggregate Crushing The aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type. Aggregate crushing was carried out in a Los Angeles drum, in accordance with the requirements of C.M. A comparative study between cone crushers and theoretically optimal crushing sequences. Miner. Eng. 2011, 24, Influence of Natural Aggregate Crushing Process on Crushing

احصل على السعر

Effects of the Parent Concrete Properties and Crushing Procedure

The physical characteristics of RCA such as the presence of adhered mortar, density, abrasion, crushing index, method of crushing, surface texture, and also the other characteristics like mixingAggregates are tested for strength, toughness, hardness, shape, and water absorption. In order to decide the suitability of the aggregate for use in pavement construction, following tests are carried out: Crushing test. Abrasion test. Impact test. Soundness test. Shape test.7 LAB TESTS ON AGGREGATE TO CHECK QUALITY FOR USE IN

احصل على السعر

Effect of crushing mechanism on the shape properties of coarse

Among the several factors, the process involved in the aggregate production plays a vital role. In this study, two different crushing sequences are considered to evaluate the effect of the

احصل على السعر