Development of a process flowsheet for the beneficiation of low

It was possible to beneficiate a low-grade iron ore fines sample from Bellary-Hospet, Karnataka, India assaying 56% Fe, 9.1% SiO2 and 5.2% Al2O3 and The iron ore fines sample was obtained from the Bellary-Hospet area, Karnataka, India for beneficiation studies. An iron ore sample of below 10 mm was used for this study. The SPECIAL IRON ORE PROCESSING ISSUE Development of a process

احصل على السعر

Development of a process flowsheet for the beneficiation of low

It was possible to beneficiate a low-grade iron ore fines sample from Bellary-Hospet, Karnataka, India assaying 56% Fe, 9.1% SiO2 and 5.2% Al2O3 and A few of these methods have been discussed here: In an attempt to understand the composition of the iron ore samples collected from the Bellary-Hospet Iron Ore Characterization Techniques in Mineral Processing

احصل على السعر

Existing and New Processes for Beneficiation of Indian

10 Citations Metrics Abstract The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making. With This chapter briefly discusses the current scenario of the iron ore resources in India, iron ore mining methodology, beneficiation technique, and the current Iron ore beneficiation: an overview ScienceDirect

احصل على السعر

Development of a process flowsheet for the beneficiation of low

It was possible to beneficiate a low-grade iron ore fines sample from Bellary-Hospet, Karnataka, India assaying 56% Fe, 9.1% SiO2 and 5.2% Al2O3 and produce two The iron-making process requires high-quality raw materials, with Fe ≥ 64% and <2% alumina and silica each, to enhance blast furnace productivity at a given Iron ore beneficiation: an overview ResearchGate

احصل على السعر

(PDF) Beneficiation and flowsheet development of a

In the present study a detailed characterization followed by beneficiation of low grade iron ore was studied. The Run of Mine (R.O.M) sample assayed 21.91 % Fe, which is very low grade in nature.Table 6- Comparative material balance between conventional and Non-conventional mode of waste recycling of iron ore mines, iron ore beneficiation plant tails and wastes from secondary steel manufacturing (PDF) Processing of solid wastes from mines, mineral

احصل على السعر

Beneficiation Strategies for Removal of Silica and Alumina from

Iron ore, the raw material for the steel industry, is critical for the sustainable development of the global economy (Yellishetty, Ranjith and Tharumarajah 2010). Global demand for iron and stee Beneficiation Strategies for Removal of Silica and Alumina from Low-Grade Hematite-Goethite Iron Ores: Mineral Processing and Since July 2020, all mines have been operationalised and in FY 2020-21, they collectively produced around 12.37 MnT of iron ore, which have been directed to our three integrated steel plants. Currently, we are exploring ways in which the production can be ramped up from the mines. Further, we are exploring setting up of beneficiation plant toJSW Steel Integrated Report 2020-21

احصل على السعر

iron ore beneficiation process pdf in bellary karnataka

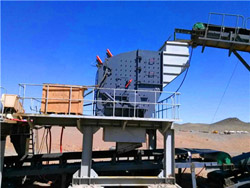

M/s Star Minerals Proposed Iron Ore/ Mn Ore Beneficiation Plant near Sanklapura, Hospet Tq., Vijayanagara Dist. Page 3 of 10 3.3 Description of Mineral Beneficiation Process: The main plant facilities proposed to be established in the project include raw material receipt and storage, weigh-bridge, crushing of the ore in the crusher(s) followed byIntroduction Iron is the fourth most abundant mineral on earth having a reserve of 170 billion tonnes of crude iron ore. Iron & steel is the driving force behind industrial development in any country.CURRENT PRACTICES IN INDIAN IRON ORE BENEFICIATION

احصل على السعر

SC relaxes iron ore mining limit for Bellary, 2 other Karnataka

THE SUPREME Court on Friday relaxed the iron ore mining limit for Bellary, Chitradurga and Tumkur districts in Karnataka, stating that “conservation of the ecology and the environment must go hand in hand with the spirit of economic development” and noting that the situation in the state had “vastly changed” since the time a ban was Methods to evaluate the liberation characteristics of an iron ore feed in a jigging plant have been given by Mukherjee et al. (2008). Das et al. (2007) studied the beneficiation of a low-grade(PDF) Effective Beneficiation of Low Grade Iron Ore Through

احصل على السعر

IBM

IBM2.M/s Soceidade de Fomento Pvt Ltd. Iron Ore Beneficiation Plant, Goa, India from 23-01-2003 to 31-12-2007. Designation : Jr. Mineral Processing Engineer Reporting to Process in-charge. Worked as a shift in-charge. Responsible for safe and trouble free operation of plant. Responsible for shift operation and process control of Resume-2 (1) PDF SlideShare

احصل على السعر

INDIAN BUREAU OF MINES MINERALS DEVELOPMEMT AND

Bellary BELLARY KARNATAKA 9448286155 Phone: FAX : Owner : DR. VINOD NOWAL DY.MANAGING DIRECTOR, M/S JSW STEEL LIMITED, NANDI IRON ORE MINE, BELLARY BELLARY KARNATAKA Phone: FAX : Agent : SUNIL KUMAR SINGH JSW steel Ltd., Vijayanagar works, Vidyanagar Po, Bellari, Karnataka BELLARY The haematite ore in South Africa is processed in a dry process to a HQ lump ore with 64 % iron content and a sintered fine ore with 63.5 % iron content. For fine ore beneficiation, wet processes are used. Capacity at the Minas Rio is to be increased from 26.5 Mta capacity to 28 Mta in the forthcoming years.Dry beneficiation of iron ore Mineral Processing

احصل على السعر

Iron ore beneficiation: an overview ScienceDirect

This was mainly achieved by selective mining of high-grade ore, keeping the cut-off to approximately 55% Fe. However, due to growing demand of the iron ore, this is not sustainable, therefore the cut-off grade is now revised by the Indian Bureau of Mines to 45% Fe for hematitic and geothitic ores. In addition to this, stringent environmentalIt has developed a process flow sheet for beneficiation of BHJ/BHQ and a demonstration pilot plant is planned to be constructed at Donimalai. It is developing process for generation of titanium slag using the hydrogen reduction facility available. It has developed process to improve screening efficiency for dry & wet screening of iron ore.BRIEF OVERVIEW OF NMDC LIMITED Ministry of Steel

احصل على السعر

SGS MINERALS SERVICES T3 SGS 960 11-2009

beneficiation techniques including: • Scrubbing • Crushing • Gravity and magnetic separation • The JKTech Drop-Weight Test measures Selective flocculation • the apparent breakage function of the Flotation SCRUBBING Scrubbing is the process whereby clays, slimes and any potential oxidization present in or on the ore typically using water.Introduction Iron is the fourth most abundant mineral on earth having a reserve of 170 billion tonnes of crude iron ore. Iron & steel is the driving force behind industrial development in any country.CURRENT PRACTICES IN INDIAN IRON ORE BENEFICIATION

احصل على السعر

Development of Beneficiation Process for High Alumina Iron Ores

Development of Beneftciation Process for High Alumina Iron Ores of Bellary Hospet Region Iron ore Source Name Feed Classifier Cyclone circuit Total circuit A1203,,.. .14.12..,3 A1203 „ Fun', Yield, % % Drop in A1203 Ai_0_ 3 3 Yield, % % Drop in A124:3 A1 0A1203 _ 3 Yield, % % drop in A1203 Class meat ionRolled out in 1997, VIjayanagar Works’ hot strip mill is today the widest in India. It can roll products of a width of up to 2100 mm. Corex technology. By being the first plant in India to use Corex technology for steel and hot metal production, our Vijayanagar Works gained an early-mover advantage and a definitive edge over the competition.JSW Vijayanagar Works Overview

احصل على السعر

SPECIAL IRON ORE PROCESSING ISSUE Development of a process

the beneficiation of low-grade iron ore fines from the Bellary-Hospet region of Karnataka, India T. Umadevi, K. Abhishek, A. Pratap Singh and R. Sah JSW Steel Ltd., India Communicating author email: [email protected] Abstract It was possible to beneficiate a low-grade iron ore fines sample from Bellary-Hospet, Karnataka, India assaying 56% Fe, 9.General Geology. Thirty-five samples representing banded iron ores were collected from Donimalai of Bellary District (Karnataka State, India). Donimalai lies under the southeast part of the Sandur schist belt (i.e., Dharwarian green stone belt), which is situated at the eastern edge of the Karnataka nucleus belonging to the Dharwar An Investigation into the Influence of α–β Quartz Phase Transition

احصل على السعر